Recently, Weite’s electrical engineers completed the installation and commissioning of the gate control system of Wan’an Power Plant. During the installation process, the construction plan was strictly followed, and the electrical procedures were checked step by step, and proceeded in an orderly manner. The final project was completed and accepted and delivered to the power plant for use.

The Wananxi Hydropower Station, invested and constructed by the National Energy Investment Corporation, is located on the Wan’an Stream, a tributary of the North Stream of the Jiulong River, Fujian Province. It is the first-level hydropower station developed by the Wan’an Stream, a tributary of the North Stream of the Jiulong River, Fujian Province. The total storage capacity is 228.9 million m³ and the regulating storage capacity is 168 million m³. It is a multi-year regulating reservoir. The main buildings of the hub are composed of a barrage, a spillway, a diversion tunnel, a powerhouse, and a booster switch station.

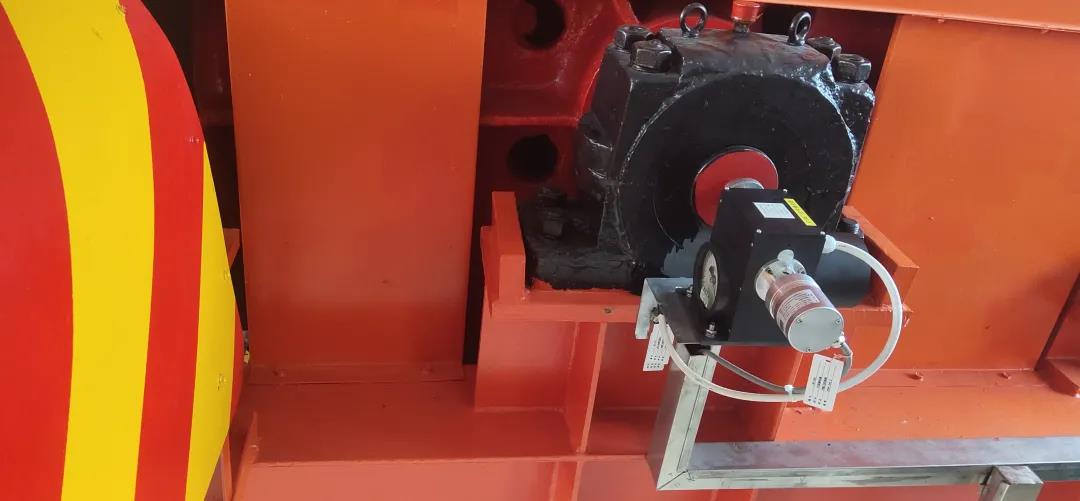

1.On-site photo of Wananxi Hydropower Station

The dam spillway gate undertakes tasks such as power generation, flood control, flood discharge, irrigation, and water supply, which requires extremely high system reliability. Therefore, the reliability of the system is the first or highest principle to be observed in the design.

The spillway hoisting room is about two kilometers away from the hydraulic duty room. There are a total of multiple arc gate gates for flood discharge. The intelligent gate control system currently in use cannot meet the automation requirements due to outdated equipment and reduced reliability also can’t realize remote control and video surveillance operations.

2.Before the project transformation

The renovation project of Weite Technologies Co., Ltd is aimed at the current situation of the Wananxi gate monitoring system. Based on the principle of reliability and advancement, it aims to solve customer pain points, make the control more intelligent, and the management more convenient. Improve the stability and safety of equipment operation.

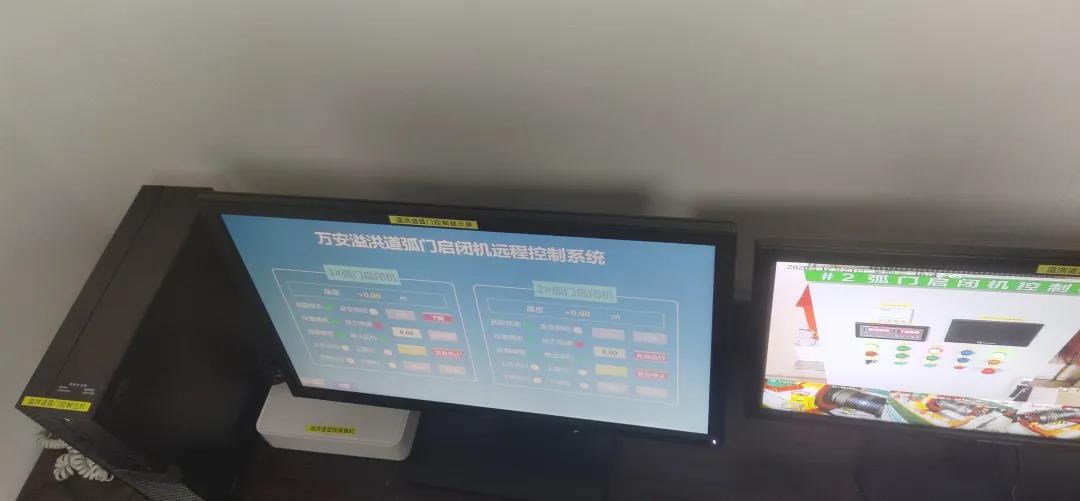

3.After the project transformation

Weite electrical engineers at the construction site deal with every installation detail rigorously and patiently debug each equipment to ensure the reliability of the system after the installation is completed. After completing the technical design and transformation of the intelligent control system of the spillway #1, #2 arc gate hoist, it will realize the on-site operation control, realize the remote operation control of the hydraulic duty room, and use the video camera in the hydraulic duty room to monitor the spillway in real time #1,#2 Arc door left winch, right winch, operation control cabinet, arc door operating status

4.Project acceptance site

The completion of the renovation of this project by Weite has solved the remote control and video monitoring operation of the intelligent gate control system for the power plant, allowing the power plant to realize operation automation in the future operation. After the equipment trial operation is completed, the project party believes that the gate control system is advanced in technology, reliable in equipment, complete in data, and meets the technical requirements, and unanimously agrees to pass the completion acceptance.

![]() Add.:No.6 Gangcheng Road,Yichang,Free Trade Zone(Hubei) China 443005

Add.:No.6 Gangcheng Road,Yichang,Free Trade Zone(Hubei) China 443005

![]() 86-15507209968(whatsapp)

86-15507209968(whatsapp)