Load Moment Indicator (Crane computer) for Mobile Crane & Crawler Crane

1. Display

Load Moment Indicator (LMI), also known as Rated Capacity Indicators (RCI), or a Safe Load Indicator (SLI) or an Automatic Safe Load Indicator (ASLI) is a device which is installed on Lattice or Crawler cranes to alert the operator if the lift is exceeding the safe operating range of the crane. In some cases, the device will physically lock the equipment in circumstances it determines to be unsafe. LMI systems are usually composed of a microprocessor connected to various sensors on the crane itself. The LMI measures the angle and extension of the boom along with the load weight and compares this with the manufacturer's specifications to determine if the lift is safe.

A safe load indicator has the capability of detecting the angle, weight of load lifted, and ground radius of any lifting device. It controls the lifting equipment to the level that it tries to keep the crane functioning as per the manufacturer's suggested safety charts.

The crane is fitted with multiple sensors, for each of the measured parameters, which are then further displayed in the operator's cabin for his benefit.

Data Logger System

When WTAU ( WTL-A700)load moment indicator system during the process, cranevarious operating parameters (weight signal, angle signal, A2B etc.) are detected by the corresponding sensors, and sent to the motherboard after signal processing, and then through the A / D Conversion, etc. to convert the signal

to the digital can be identified by the CPU; and then indicate the data by the display through the RS485;the entire operating data is record every 2-5 seconds and save in memory.

Data Logger System Function

The data logger system records the moment system parameters and the alarm data of moment system for crane in using status.The data logger protects the parameters and system data.If there are security incidents, these parameters provide the parameters and data for the crane operation; Equipment maintenance personnel can also use data to analysis system performance and make reference forequipment maintenance.

Data Record Capacity

1 record per second, 1 hour is 3600 records, 24 hours a day continuous record, then the day is3600 * 24 = 86400 records. Each record 180 bytes (the longest), then total of 15.6M per day data, about 16M. If Encrypted data, 4G memory, can only be calculated by 2G, that is 1870M. 1870/16 = 116.5 days ,4G memory can record about 4 months.

1 record per 2 seconds, 1 hour is 1800 records, 24 hours a day continuous record, then the day is 1800 * 24 = 43200 records. Each record 180 bytes (the longest), then total of 7.8 M per day data, about 8 M. If Encrypted data, 4G memory, can only be calculated by 2G, that is 1870M. 1870/8 =233 days .4G

memory can record about 8 months.

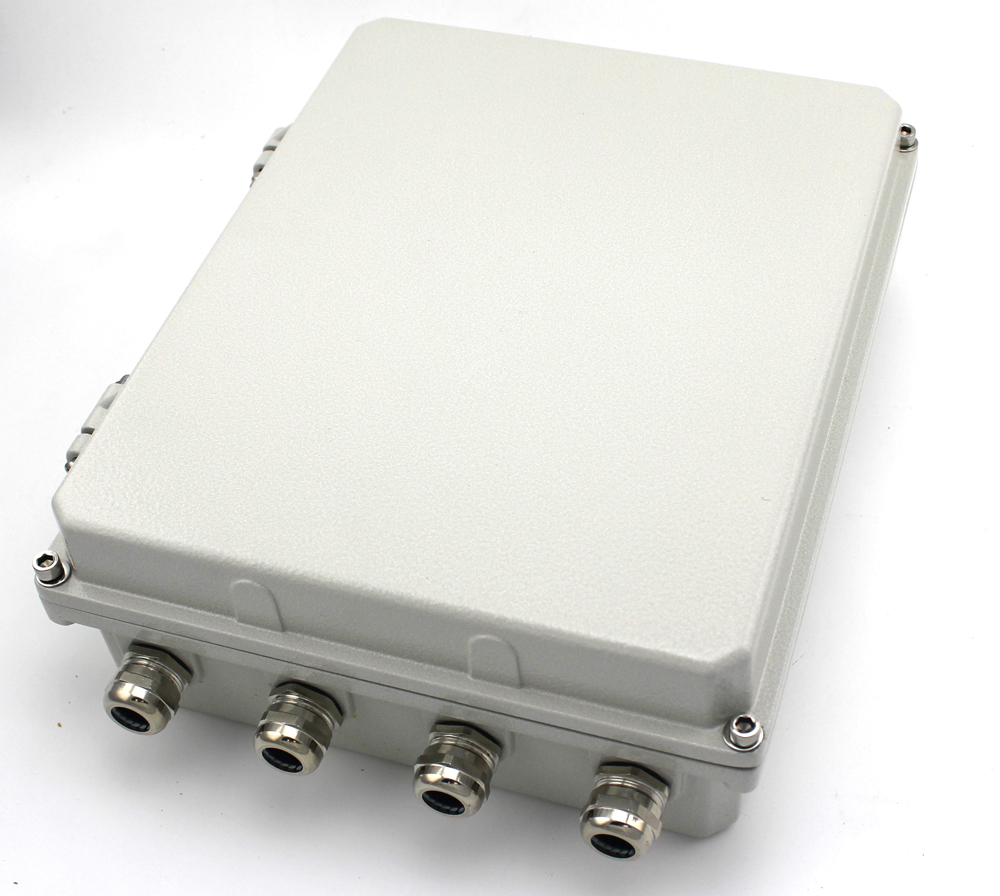

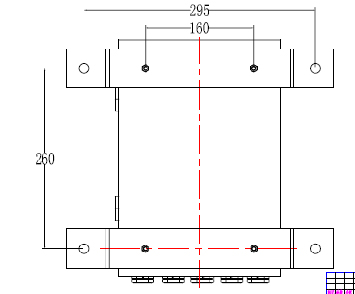

2. Data control box

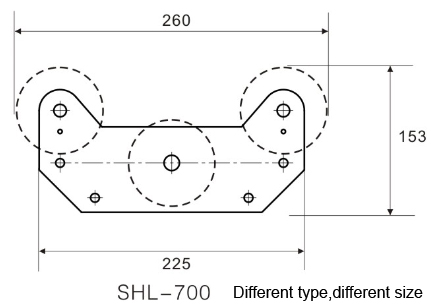

3. SHL Rope Rider three-pully load sensor

SHL Load Cell Sensor Main Parameters

○ Rated capacity: 10, 15, 20, 25, 30, 40, 50t

○ Safe overload: 150%F.S

○ Material: Alloy steel

○ Sealed IP: IP68

JD-180 type Angle Sensor is composed of high reliability and anti-interference industrial grade single chip microcomputer and high reliability magnetic flux sensor

and driving chip; High integration, reliability, high precision, strong anti magnetic field interference horizontal azimuth monitoring, with SPI interface, can support

output angle, with North calibration and hard magnetic compensation function. It can be installed on crane boom.

Crane Boom Angle Sensor Main parameters

○ Single axis output angle range: -60°~+120°

○ Single axis output: RS485, SPI interface, 4-20mA

○ Dual axis output angle range: + 45°

○ Water Resistance: Waterproof

○ IP rate: IP67

5. GJ type A2B switch

It is an appropriate weight of the hammer supporting the use of hook up and down movement to hold up or disconnect or turn-on switch, put down the

hammer to achieve the purpose of automatically cut off the hoist power supply connected braking system to limit rope over volume, and reach hook in the

purpose of a certain height within the lift.

GJ Main type

○ GJ-1 :to reach the peak normally open ( hook across the boom, loop disconnect)

○ GJ-3: to reach the peak normally closed (hook met crane, closed loop)

Main parameters

○ Applies to DC and AC voltage 12 ~ 380V; Rated current: 5A.

○ Rated current: 10A

○ Supporting the external hammer weight: ≥ 1.7kg.

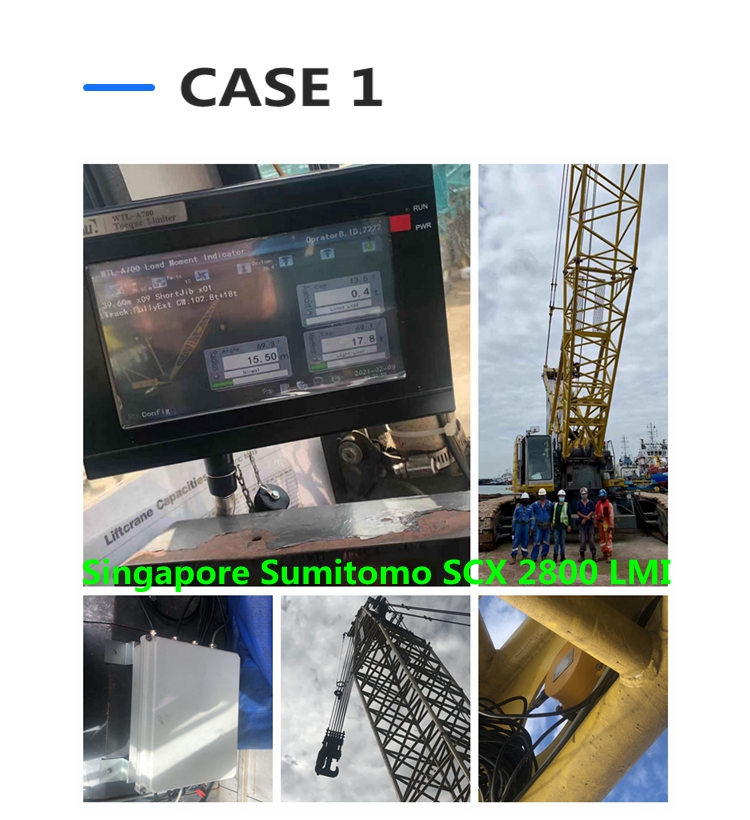

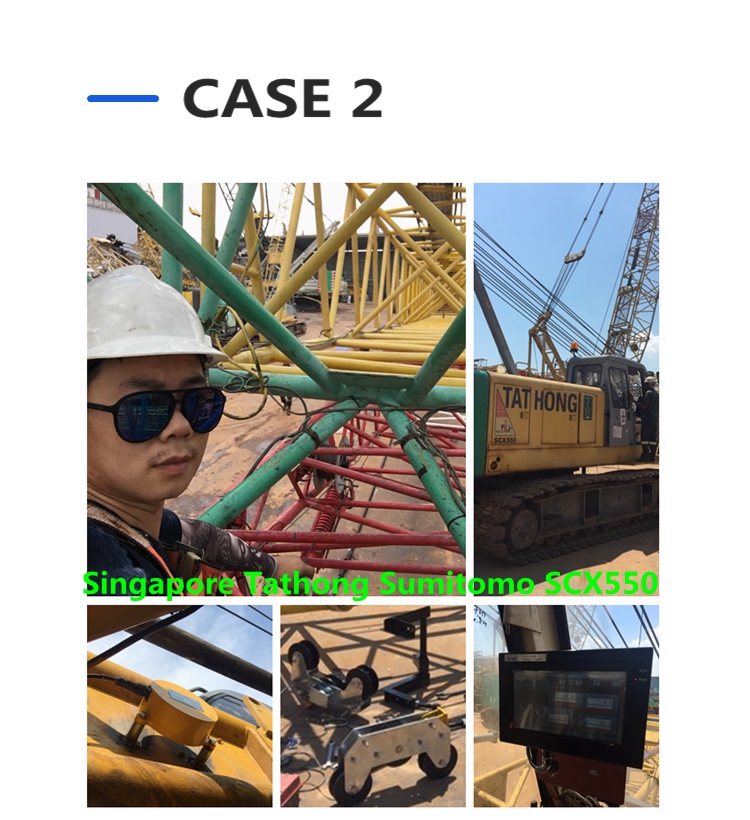

6. Application Cases

![]() Add.:No.6 Gangcheng Road,Yichang,Free Trade Zone(Hubei) China 443005

Add.:No.6 Gangcheng Road,Yichang,Free Trade Zone(Hubei) China 443005

![]() 86-15507209968(whatsapp)

86-15507209968(whatsapp)