Weite Wire Rope Nondestructive Tester

Design Concept

The design of the Weite steel wire rope non-destructive testing sensor follows the design concept of form following function, and discards all unnecessary modeling designs. On the premise of ensuring perfect functions, the minimalist design should be achieved as much as possible to reduce the weight of the product itself, so that it can be installed and used quickly and easily in complex and extreme use environments; Thor's Hammer's shape design is simple and elegant, and at the same time gives people a safe and reliable impression, which is in line with its safety monitoring industrial product positioning

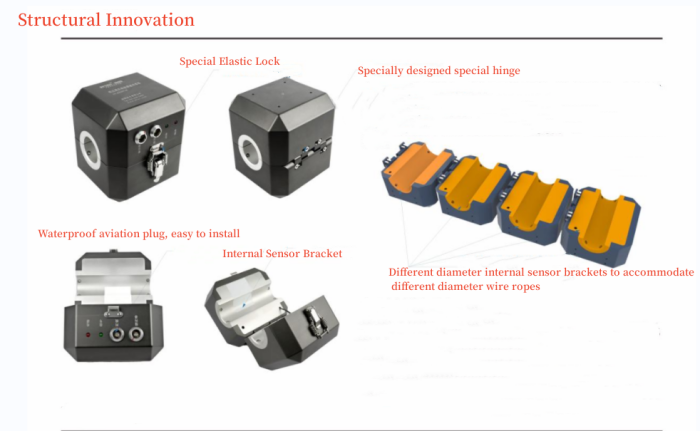

Structural Innovation

Since the upper and lower magnetic poles of the strong magnets used repel each other, the special opening and closing structure of the sensor is specially designed. The combination of the specially designed hinge and the elastic lock makes it easy to open and close and easy to install. At the same time, it can ensure that when there is a large kink on the wire rope, the lock buckle will be released to allow the wire rope to pass through, so as to avoid the sensor from jamming the wire rope or being involved in other equipment such as reels and causing major accidents or losses.

All-aluminum alloy materials are integrally processed and formed, and the shell itself has the characteristics of high strength, good processing performance and strong corrosion resistance, so as to ensure that it can be applied to various special and extreme wire rope testing environments such as ports, steel mills, mines, and cableways. , At the same time, the formation of self-shielding greatly reduces the interference of external electromagnetic fields, ensuring the accuracy and reliability of the test results.

The selection of waterproof aviation plug and the special design of the internal bracket make it have high dustproof and waterproof performance, ensuring the stability and reliability of its internal structure.

The replaceable internal bracket design of the sensor is adopted. Only by replacing the internal bracket can assure the same set of housings to be able to detect steel wire ropes with different diameters of 25-50mm.

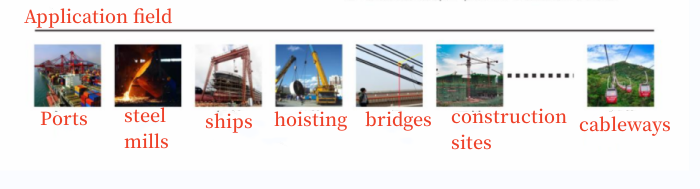

Application field

Ports, steel mills, ships, hoisting, bridges, construction sites, cableways

Crane online fault diagnosis multi-dimensional analysis system

The crane fault diagnosis comprehensive spectrum diagnosis method innovatively developed by Weite conducts related core technology research from the perspective of multi-dimensional integrated analysis of test data to ensure the safety of crane operation: for the analysis of variable speed vibration data of cranes, develop corresponding multi-dimensional analysis algorithms, general dynamic Data analysis algorithm and fault feature extraction algorithm

The crane fault diagnosis comprehensive spectrum diagnosis method innovatively developed by Weite conducts related core technology research from the perspective of multi-dimensional integrated analysis of test data to ensure the safety of crane operation: for the analysis of variable speed vibration data of cranes, develop corresponding multi-dimensional analysis algorithms, general dynamic Data analysis algorithm and fault feature extraction algorithm

The algorithm tool set developed for the complexity of the comprehensive fault spectrum integrates a variety of time-frequency domain analysis methods to support the data analysis platform, and realizes low-frequency and wide-range data analysis, dynamic data analysis, nonlinear and unstable fault feature extraction, fault diagnosis and fault diagnosis Forecast, generally applicable to all types of cranes.

Weite crane online fault diagnosis multi-dimensional analysis system has three categories of functions: classic diagnosis, fine diagnosis and intelligent prediction.

Classical diagnosis: time domain analysis (autocorrelation analysis, cross-correlation analysis), frequency domain analysis (power spectrum analysis, cepstrum analysis, envelope spectrum analysis, cross-spectrum analysis), played a major role in the early failure analysis of rotating equipment The classic signal analysis methods are based on Fourier transform and are suitable for stationary signals.

Fine analysis: Using wavelet analysis (linear) and Wigner analysis (non-linear) filter demodulation method, adaptive high-frequency demodulation method, intensity spectrum and integrated spectrum and other modern spectrum analysis techniques use time-frequency analysis method to identify short Special signals such as duration sine wave and chirp pulse can effectively extract fault features

Intelligent diagnosis: The self-developed order generalization method based on smooth pseudo-Wigner distribution can adaptively adjust the order resolution, and the minimum order resolution is not less than 1/32. Variable load alarm threshold self-learning function and intelligent early warning Function

The comprehensive spectrum diagnosis method independently developed by Weite has a variety of crane fault diagnosis methods and can comprehensively carry out automatic fault diagnosis. The accuracy rate of a single diagnosis method is >85%, and the comprehensive spectrum diagnosis result includes a fault accuracy rate of >90%.

Crane online fault diagnosis multi-dimensional analysis system solves four major problems of mechanical faults

hard to find

Difficult to repair

big loss

highly prone to failure

In the operation of modern production enterprises, the loss caused by equipment failure and downtime is very huge. The traditional equipment maintenance method only relies on manual work. The operation and maintenance work mainly adopts the "fire fighting" mode of finding and solving problems. The preventive maintenance is poor, and it is difficult to reduce the failure rate. The predictive management is a long way to go.

The multi-dimensional analysis system for online fault diagnosis of cranes developed by Weite Technology Co., Ltd. comprehensively collects equipment information, implements effective status monitoring and fault diagnosis of equipment, and accurately analyzes and predicts in advance, which solves the intelligent needs of enterprises for equipment management and becomes an industrial informatization , an important part of intelligent management.

The multi-dimensional analysis system for on-line diagnosis of Weite cranes is a special collection and recording of vibration, speed, temperature, current and other state signals of crane equipment, and performs signal fusion analysis, comprehensive fault diagnosis intelligent diagnosis algorithm, and realizes the crane equipment. Real-time intelligent diagnosis, fault warning and prediction, trend analysis, offline data analysis, etc., to identify the operating status and fault type of the system, predict faults in advance, reduce maintenance costs, and ensure safe production of cranes

![]() Add.:No.6 Gangcheng Road,Yichang,Free Trade Zone(Hubei) China 443005

Add.:No.6 Gangcheng Road,Yichang,Free Trade Zone(Hubei) China 443005

![]() 86-15507209968(whatsapp)

86-15507209968(whatsapp)