As a lifting device for erecting prefabricated beams, bridge erecting machines are widely used in highway and railway bridge construction projects. As large-scale special equipment, the risk factor has always been high in complex and changeable construction environments. Major accidents of overturning and rollover are not uncommon.

Application

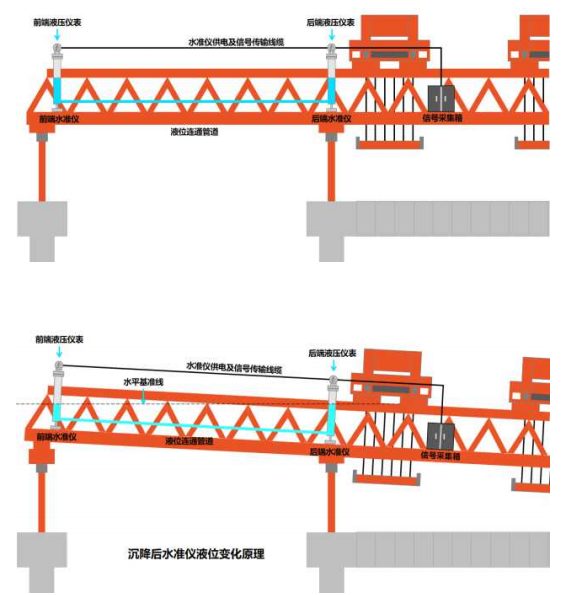

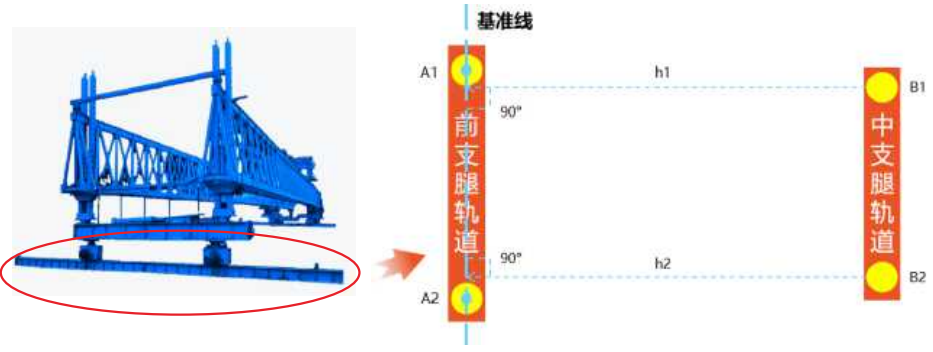

This time we mainly adopted real-time monitoring for the front high and rear low posture of the bridge erecting machine during the hole passing and beam erection process, as well as the parallelism status of the front and middle outrigger tracks during the lateral movement of the whole machine, so that the bridge erecting machine can Maintain a good operating posture, reduce the safety risks caused by instability, and make the bridge erecting machine run safer and manage more efficiently.

Field Application Issues and Risks

During the use of the beam through-hole, it is measured by a manual ruler, which is difficult to adjust and takes a long time to adjust: the distance between the bridge piers is large, and the measurement error of the tape measure is large; personnel stand on the cover beam to adjust, and the safety risk is great.

Technical solution

Customers can monitor the parallelism of the track, watch the length of h1 and h2 displayed on the LED screen, and the difference between the two lines, and complete the adjustment of the parallelism of the two track beams. It saves the process of manual ruler measurement and the risk of large measurement errors. The driver can check the height difference of the front and rear outriggers at any time through the value displayed on the height difference instrument, so that the bridge erecting machine is always running in a safe state.

Product and service delivery

The parallelism monitoring and height difference monitoring system developed and installed by Weite Technologies Co., Ltd. can realize accurate distance measurement, and the error is controlled within millimeters.

Successfully solved the problems of difficult adjustment, large error and high risk for customers. The site successfully passed the customer acceptance and was well received by customers.

Feedback

During the whole project process, based on the principle of customer first, Weite successfully solved the technical problems for the customer. The distance measurement of the product was accurate during the use process, and all functions met the technical requirements and passed the acceptance test. At the same time, customers express their approval of our company's products!

![]() Add.:No.6 Gangcheng Road,Yichang,Free Trade Zone(Hubei) China 443005

Add.:No.6 Gangcheng Road,Yichang,Free Trade Zone(Hubei) China 443005

![]() 86-15507209968(whatsapp)

86-15507209968(whatsapp)