Recently, Weite's convenient fault diagnosis multi-dimensional analysis system was used for a large shipyard bridge crane. The equipment's flexible, convenient, efficient and accurate analysis of equipment faults and damage levels was praised by users. The on-site output of "Fault Diagnosis Analysis Report" provides suggestions and data for equipment maintenance and management, improving work efficiency and saving operation and maintenance costs.

Weite experts came to the scene together with users

Carry out equipment inspections and check whether all components of the equipment are complete, whether the power is sufficient, and whether they are working properly.

Carrying equipment into the factory

Board the large bridge crane and have a panoramic view of the oversized factory building. When you enter, the large half bridge crane seems small.

First, let’s experience the hoisting mechanism of a large bridge crane

Take out the sensor from the equipment box and install it

Magnetic sensor, easy to install

The equipment can collect signals from multiple channels and multiple measuring points, and can detect multiple motors and bearings at the same time.

The equipment box has a built-in power supply. Connect the sensor signal line to the equipment box and turn on the handheld industrial computer to start working.

Start the operation of the lifting equipment, open the "real-time sampling" system to start collecting data, and collect valid data for more than 5 minutes. After the collection is completed, the lifting equipment can be stopped.

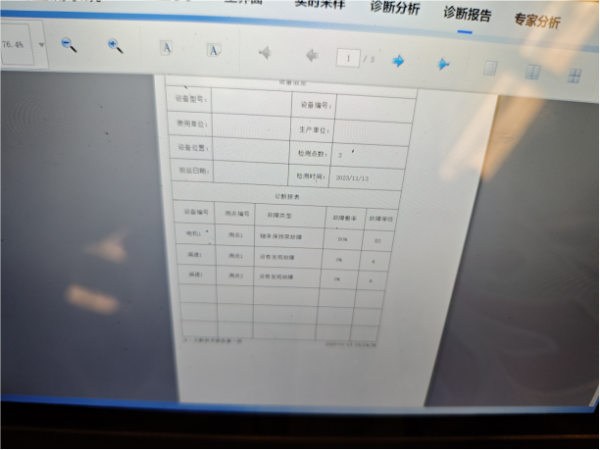

After "real-time sampling" ends, the system starts "diagnostic analysis", and a "diagnostic report" is generated when the analysis is completed.

View the electronic version of the "Diagnostic Report"

Experts reviewed and explained on site. The test conclusions in the report clearly stated the type, probability, degree of damage and suggestions of the fault.

The system supports more than 14 types of analysis maps in different dimensions. You can view the analysis by opening "Expert Analysis".

At this point, the fault diagnosis analysis of the large crane hoisting mechanism ends.

Then do a physical examination of the traveling mechanism of the large bridge crane

Remove the sensor from the lifting mechanism and install it on the traveling motor and reducer.

Magnetic sensors can be installed in minutes

Start the large bridge crane to start walking, turn on the "real-time sampling" system to start collecting data, and collect valid data for more than 5 minutes. You can stop the car after the collection is completed.

Generate diagnostic report

At this point, the fault diagnosis analysis of the traveling mechanism of the bridge crane ends.

During this visit, a fault diagnosis and analysis was performed on the hoisting mechanism and traveling mechanism of a large bridge crane in a certain shipyard. The entire process was completed in less than one hour.

![]() Add.:No.6 Gangcheng Road,Yichang,Free Trade Zone(Hubei) China 443005

Add.:No.6 Gangcheng Road,Yichang,Free Trade Zone(Hubei) China 443005

![]() 86-15507209968(whatsapp)

86-15507209968(whatsapp)