Driver fatigue and distraction warning system

The fatigue and distraction warning system uses smart cameras to monitor the driver in real time, uses graphical algorithms to analyze and process the driver's images frame by frame, and identifies the driver's facial state, body posture, use of mobile phones or objects, etc. in real time, and determines through logical judgment and rule algorithms. Check whether the driver is tired and performs abnormal operations such as making phone calls. The system is highly practical and does not affect the driver's normal work. After the device is installed, an alarm will sound to remind the driver when there is abnormal behavior, and it will remain quiet and noise-free for the rest of the time.

Factory explosion-proof driving safety solutions

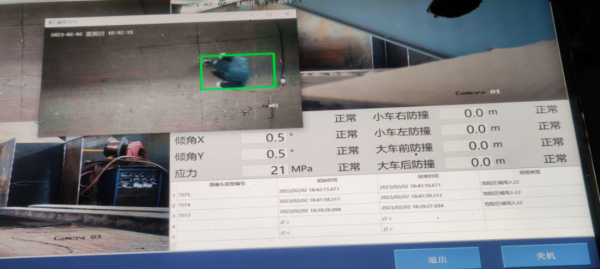

The anti-collision radar system monitors the bottom of the hook in real time. When dangerous targets (such as pedestrians, goods or other stacked objects) appear, the radar system sends an alarm to the crane driver in advance, allowing the driver to respond in time. At the same time, the radar output signal reaches the crane control The system automatically stops or slows down according to the situation.

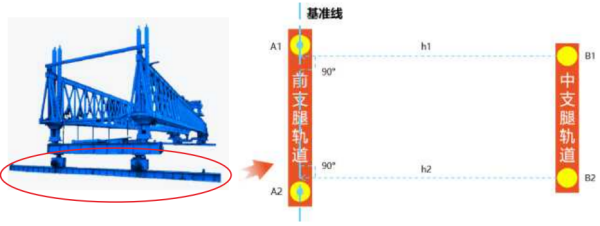

Bridge erecting machine attitude monitoring solution

The product mainly monitors the front high and rear low posture of the bridge erecting machine during the process of passing holes and erecting beams, as well as the parallelism status of the front and middle outrigger tracks during the traverse movement of the whole machine, so that the bridge erecting machine can maintain good performance during the construction process. The operating posture reduces the safety risks caused by instability, making the bridge erecting machine safer to operate and more efficient to manage.

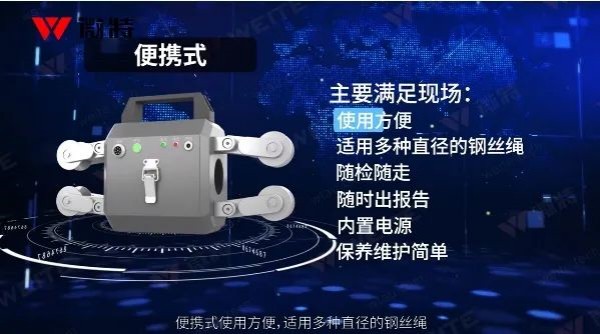

Construction crane safety technology solutions

The Weite portable wire rope non-destructive testing system is easy to use and is suitable for wire ropes of various diameters. It can be inspected on the go and reports can be issued at any time. It has a built-in power supply and is easy to maintain. The system provides customers with scientific and effective wire rope maintenance solutions. It can not only be used independently, but also provide important wire rope health data and analysis reports to the intelligent equipment maintenance platform, which is an indispensable part of future smart management.

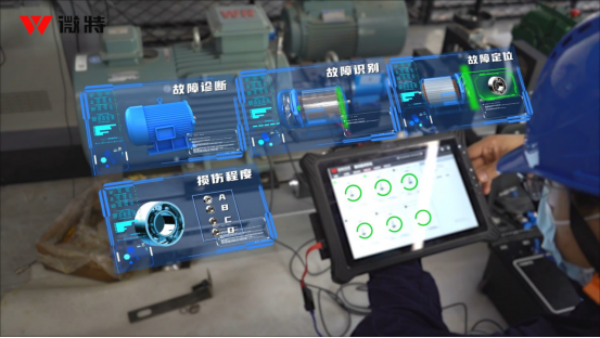

Convenient fault diagnosis multi-dimensional analysis system

This equipment integrates the function of an online fault diagnosis system, making it more flexible and convenient to use. If you need to diagnose the equipment, just lift the equipment box and go to the site to perform analysis, diagnosis and report. Transform from fixed "expert consultation" to convenient "expert door-to-door" service.

The convenient fault diagnosis multi-dimensional analysis system is suitable for rotating or reciprocating mechanical equipment such as motors, reducers, water pumps, and fans. It is mainly composed of three major hardware components: a portable sensor, a collector and a diagnostic industrial computer. It is easy to use and simple to operate. The convenient industrial computer diagnostic program has 5 special functions.

(1) Supports simultaneous acquisition and diagnosis of multiple devices and multiple measuring points to improve device diagnosis efficiency.

(2) The database has built-in multiple bearing parameters and supports adding custom bearings and their parameters.

(3) Real-time dynamic data collection, synchronous display of waveforms and calculated characteristic value parameters.

(4) Rapid equipment diagnosis can be completed in half an hour, and a diagnostic report can be output after completion.

(5) It has the "expert analysis" graph function, and can independently select more than 12 kinds of analysis graphs in multiple dimensions such as trend graphs and power spectra, which facilitates easy diagnosis, convenient review, and flexible extraction.

Weite fault diagnosis multi-dimensional analysis system uses high-precision and high-frequency sensors, which can efficiently and accurately realize fault diagnosis, fault identification, fault location, and judgment of fault damage degree, thereby achieving the effect of health diagnosis.

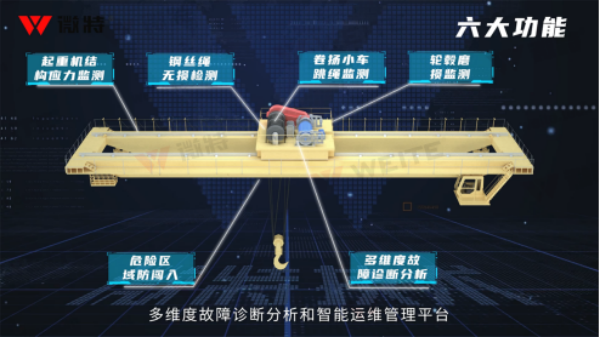

Crane intelligent operation and maintenance management system

Traditional lifting equipment intrinsic safety testing mainly relies on manual inspection + scheduled maintenance mode, which is inefficient, unreliable, difficult to manage, and prone to under-maintenance or over-maintenance.

Taking the bridge crane in the stamping workshop of the automobile manufacturing industry as an example, the system mainly consists of seven parts: illegal intrusion system for people in the work area, crane stress detection, hub wear monitoring, wire rope damage detection, winch skipping monitoring, fault diagnosis analysis, large Data software platform and driver behavior monitoring, etc.

The intelligent operation and maintenance management system of micro-te bridge crane uses advanced technology + practical operation and maintenance management model to improve the quality of operation and maintenance work, improve efficiency and reduce costs.

Hydropower station intelligent gantry crane

The smart door operator realizes the function of automatically lifting and lowering the designated gate through one-button operation. On the basis of retaining the metal structure and mechanical transmission mechanism of the original equipment, various sensors such as Beidou, UWB, radar, optical fiber, and vibration are installed. After intelligent upgrade, its equipment has the capabilities of sensing, planning, execution, collaboration, learning, data and information management.

The intelligent upgrade and renovation of the hydropower station door operator is designed based on the gate lifting and lowering process, and realizes automatic positioning of the door operator, automatic anti-collision during trolley operation and trolley operation, independent path planning, automatic recognition and alignment of the gate and automatic locking of the gate, and anti-sway of the spreader. , process abnormality judgment, door library management, early diagnosis of key metal structures and driving structures, etc. It breaks the traditional work and management model that is mainly manual and assisted by simple mechanical equipment, bringing the hydropower station door machine into a highly intelligent era.

Crane equipment online fault and predictive maintenance platform

The Weite fault diagnosis multi-dimensional analysis system installs vibration, temperature, current, speed and other sensors on rotating equipment such as motors and reducers, collects multi-dimensional status signals in real time, performs fusion analysis, and combines intelligent diagnosis algorithms to realize crane equipment Real-time intelligent diagnosis, early warning forecast, trend analysis and other functions.

The diagnostic report can analyze the fault type, fault probability, and fault level, and provide maintenance recommendations. The types of faults include bearing misalignment, imbalance, looseness, shaft bending, inner and outer ring wear, ball failure, gear meshing, broken gear teeth, and stone cracks. There are more than ten fault types and five fault levels, including broken rotor bars, loose structures, and lubrication problems.

![]() Add.:No.6 Gangcheng Road,Yichang,Free Trade Zone(Hubei) China 443005

Add.:No.6 Gangcheng Road,Yichang,Free Trade Zone(Hubei) China 443005

![]() 86-15507209968(whatsapp)

86-15507209968(whatsapp)